ACOMA Products: Guarantee of Uniformity during Printing

In the context of printing, the consistency of material volume is crucial across various sectors, from packaging to plastic cups, and even newspapers. Volume stability is a prerequisite for achieving superior final products, directly impacting reliability and functionality.

Variable dimensions not only compromise the quality outcome but also negatively influence production efficiency. Consistency and uniformity of thickness are fundamental requirements to meet the demanded quality standards.

The Challenge of Integrity during Printing

ACOMA stands out for employing cutting-edge machinery, sustainable materials, and highly efficient processes. This combination provides absolute control over the production process, ensuring that each printing blankets or varnishing plates maintains its shape and specified dimensions. All ACOMA products DO NOT LOSE THICKNESS DURING PRINTING!

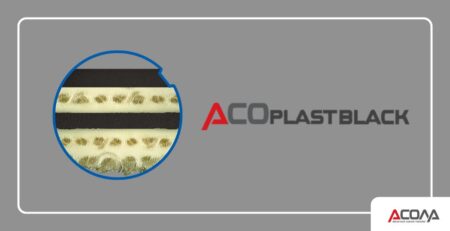

Research and Innovation for Excellent Materials

Research and development play a key role in perfecting ACOMA products. The reliability and sustainability of the process are its indispensable pillars. Producing items that retain their thickness not only provides a competitive advantage but also represents a step toward waste reduction and resource optimization.

Preserving volume during printing is a fundamental aspect of ensuring high-quality products. ACOMA ensures product excellence and progresses towards a more sustainable production.